Water Expo 2025 in New Delhi 28-30 August 2025 | Pragati Maidan, New Delhi India 20th Everything About Water Expo 2025 ...

Decoding CPCB and NGT Compliance for ETP Plants in Delhi NCR

Effluent Treatment Plant (ETP) from reliable ETP Plant Manufacturers play a key role in reducing industrial pollution by treating wastewater before its release into the environment.

What is an Effluent Treatment Plant?

An effluent treatment plant from a reliable ETP Plant Manufacturer in Delhi NCR is a facility meticulously designed to treat wastewater referred to as effluent. The effluents are produced by industrial operations and are harmful to the environment, marine life and humans.

Effluent Treatment Plant removes the harmful contaminants before the water is discharged back into the environment or reused within the industrial processes. The main aim of ETP is to reduce the adverse effects of industrial waste on the environment and public health by adhering to the regulatory norms for wastewater discharge.

The important processes of ETP are

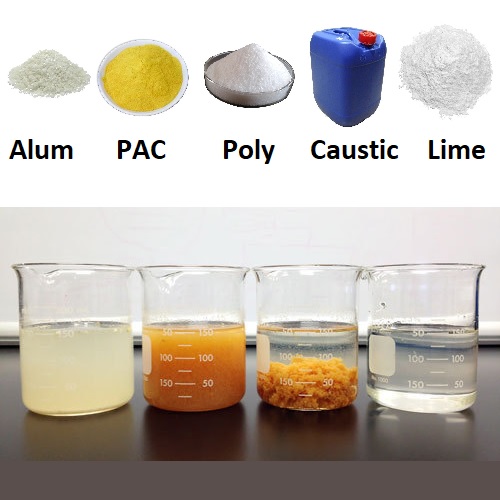

- Preliminary Treatment: In this process, large solids and debris are removed from the wastewater to prevent damage to the subsequent treatment units. The ETP eliminates heavy inorganic particles like sand and gravel that can cause abrasion to the equipment.

- Primary Treatment: The Sedimentation process allows suspended solids to settle at the bottom of sedimentation tanks, forming sludge that is removed later.

- Secondary Treatment: In this process, the microorganisms are used to decompose dissolved organic matter. Activated sludge process and trickling filters are used in this treatment process.

- Tertiary Treatment: This advanced treatment starts with filtration where the residual suspended solids are removed through sand filters or membrane filtration. The process employs chemical agents like chlorine or physical methods like ultraviolet radiation to remove pathogenic microorganisms. The nutrient removal process targets the reduction of nutrients like nitrogen and phosphorous to prevent eutrophication in receiving water bodies.

- Sludge Treatment and Disposal: In this process, the concentrated sludge minimises its volume making it easier to handle and dispose of. Anaerobic digestion stabilizes organic matter in the sludge, minimizing odours and pathogens. The treated sludge can be disposed of in landfills, incinerated or repurposed as soil conditioners, based on local norms and composition.

In Delhi, NCR the industries and manufacturing units must be in compliance with the CPCB norms for industrial wastewater and NGT orders on pollution control.

CPCB and NGT Overview

The Central Pollution Control Board (CPCB) is an apex body responsible for pollution control in India. The board formulates standards for the discharge of environmental pollution and provides technical guidance to the industries.

National Green Tribunal (NGT) is a specialized judicial body dedicated to expeditious environmental dispute resolution and enforcement of legal rights relating to the environment.

CPCB Guidelines for ETP Plants

The CPCB has laid down specific effluent standards for various industries ensuring wastewater discharges do not harm the environment. The effluent standards for ETPs in India laid down by CPCB are-

- Industry-Specific Standards: The CPCB has outlined effluent standards for numerous industries, including pharmaceuticals, textiles and chemicals. These norms highlight the permissible limits for pollutants like biological oxygen demand, chemical oxygen demand, total suspended solids and specific hazardous chemicals.

- Technical Guidance: The CPCB provides technical guidelines and SOPs to help industries in achieving compliance. The guidelines contain aspects like the design, operation and maintenance of ETPs, ensuring that industries implement effective wastewater treatment solutions.

NGT Compliance for Wastewater Treatment

NGT has been proactive in addressing environmental concerns related to industrial effluents.

- Functional ETPs mandatory: NGT has directed that industries must operate functional primary effluent treatment plants. The establishment and operation of Common Effluent Treatment Plants have been emphasized with specific timelines for implementation.

- Environmental compensation for non-compliance: To deter non-compliance the NGT has instructed CPCB to develop an environmental compensation regime for non-complying ETPs. The compensation is part of NGT guidelines for environmental protection and involves levying fines according to factors like duration of non-compliance, pollution index and scale of operations.

CPCB Compliance checklist for industries in Delhi, NCR

- Inspections have revealed that only a fraction of common effluent treatment plants in the national capital meet the prescribed norms, leading to untreated or partially treated effluents being discharged into water bodies like the Yamuna River.

- Many common effluent treatment plants operate below their designed capacities because of inadequate wastewater inflow, because the industries lack proper connections to these plants or are non-operational.

What are the ETP regulations in Delhi NCR?

Effluent Treatment Plants are essential for treating industrial wastewater to meet environmental norms before discharge. In Delhi, NCR ETP norms are governed by the framework of laws, guidelines and standards ensuring ecological protection.

- Legal Norms: The Water Prevention and Control of Pollution Act 1974, establishes the foundation for preventing and controlling water pollution, mandating industries to treat effluent before discharge. The Environmental Protection Act 1986 empowers the government to set norms for environmental quality and regulate industrial discharges. The Delhi Common Effluent Treatment Plants Act 2000 addresses the establishment and operation of common effluent treatment plants in Delhi, outlining responsibilities and cost-sharing mechanisms among the industrial units.

- Effluent Discharge Norms: The CPCB sets industry-specific effluent discharge norms, highlighting permissible limits for pollutants like pH levels, BOD, COD and TSS. For the common effluent treatment plants in Delhi, the treated effluent quality norms are prescribed to ensure compliance with environmental norms.

- Responsibilities of Industrial Units: Industries in designated areas must be members of common effluent treatment plant societies responsible for collective wastewater treatment. The industries are required to pre-treat their effluents to meet inlet quality norms of the ETPs ensuring effectiveness of collective treatment processes.

- CETP societies functions: These societies are responsible for the proper functioning and upkeep of treatment plants ensuring compliance with the environmental norms. The societies must adopt cutting-edge treatment technologies as required to meet the changing environmental needs.

- Monitoring and Compliance: Industries and ETP societies are mandated to regularly monitor effluent quality and submit reports to regulatory authorities. The DPCC – Delhi Pollution Control Board conducts periodic inspections to verify compliance with effluent norms and operational protocols.

- Penalties for non-compliance: Non-compliance with effluent norms or operational guidelines can result in monetary fines, calculated based on the severity and duration of the violation. Continuous non-compliance will lead to orders of closing down the facility or restrictions on industrial operations until compliance is achieved.

- Public Participation and Transparency: Regulatory authorities are required to make information regarding effluent norms, compliance statuses and enforcement actions publicly accessible. Consulting with the public and meetings with stakeholders are encouraged to involve communities in environmental decision-making processes.

- Recent developments: To combat increasing pollution levels in the national capital, regulatory bodies are revising effluent norms to impose stricter limits on pollutants. The industries are encouraged to adopt cutting-edge treatment technologies like membrane bioreactors and zero-liquid discharge systems to increase treatment efficiency.

Delhi NCR water pollution regulations

Water pollution in Delhi NCR is a major concern requiring a strong regulatory framework to safeguard public health and the environment. The norms highlight laws, authorities and enforcement mechanisms aimed at controlling and reducing water pollution.

- Consent: The Industries in Delhi can obtain consent to establish and consent to operate from the DPCC. These consents ensure that the industrial units comply with the ecological norms and operate pollution control devices effectively.

- Key legislative Acts: The major acts like the Water (Prevention and Control of Pollution) Act, of 1974 and the Environmental (Protection) Act, of 1986 prevent and control water pollution. The 1974 Act establishes norms for effluent discharge and empowers authorities to enforce compliance. The 1986 Act provides the central government with comprehensive powers to regulate environmental pollution including water pollution.

- Regulatory Authorities: CPCB was established under the Water Act of 1974 and formulates national norms for pollution control. The regulatory body provides technical guidance to the state boards. DPCC, an autonomous body functions as the pollution control authority for Delhi. It implements environmental policies, monitors pollution levels and enforces norms within the National Capital Territory.

- Effluent Discharge Standards: Industries are mandated to treat wastewater to meet the specific norms before discharge. The CPCB in collaboration with the DPCC sets norms that vary according to the industry type and nature of the pollutants.

- Monitoring: DPCC conducts regular inspections of the industrial units to verify whether they are working according to the environmental norms. Non-compliance results in penalties, fines, closure orders or imprisonment according to the severity of the violation.

- NGT’s Role: Established under the National Green Tribunal Act of 2010, NGT is a specialized judicial body that arbitrates environmental disputes, including those related to water pollution ensuring expeditious resolution and enforcement of legal rights.

- Yamuna River: The Yamuna River flowing through Delhi suffers from significant pollution due to untreated wastewater and industrial discharges. Despite regulations, challenges persist in effectively treating and managing wastewater causing environmental and health issues. However, after the election of the new state government new norms and policies are formed for cleaning the Yamuna River and the cleaning process has started in full swing.

Challenges in achieving compliance

- Technological limitations: Some industries in Delhi lack access to cutting-edge ETPs resulting in subpar effluent quality.

- Financial Constraints: Small and medium enterprises often face financial hurdles in establishing and maintaining efficient ETPs.

- Awareness and Training: There is a need for increased awareness and training among industry personnel regarding environmental norms and best practices in wastewater management.

What are the recommendations industries and regulatory bodies need to take for improved ETP compliance?

- Organizing training programs for industry stakeholders on ETP operation and maintenance as well as regulatory norms.

- Provide subsidies or low-interest loans to industries, particularly small-scale units to upgrade their wastewater treatment facilities.

- Enhance public awareness regarding the environmental impact of industrial effluents to foster community participation in monitoring and reporting violations.

- Encourage the adoption of advanced and cost-effective treatment technologies to improve effluent quality.

Why ETP compliance with CPCB and NGT directives is important?

Ensuring that ETPs comply with directives from the CPCB and the NGT is important for industries. The importance of this compliance can be highlighted through the following points.

- Legal Obligation: The CPCB establishes norms and standards for wastewater treatment to prevent environmental pollution. The non-compliance can result in legal actions including fines and even unit closure.

- Protection of the environment: Properly functioning ETPs ensure that industrial wastes are treated to remove harmful effluent before being discharged into the water bodies to prevent water pollution and protect marine life.

- Public Health and Safety: Untreated or inadequately treated industrial effluent contains harmful substances that cause significant health risks to nearby communities including waterborne diseases and exposure to toxic chemicals.

- Sustainability: Effective water treatment allows for the reuse of water in various industrial processes like cleaning, irrigation and landscaping. This reduces the demand for freshwater, promoting a sustainable future.

- Avoiding Penalties: Non-compliance with the CPCB and NGT directives can lead to huge fines.

- Operational Efficiency: Maintaining ETPs can lead to improved operational efficiency by minimizing waste, including conserving resources and lowering treatment costs over time.

- CSR: Adhering to the ETP compliance epitomizes the commitment of the company to social responsibility, increasing its reputation and fostering positive relationships with the community.

- Legal Compliance: Compliance with NGT and CPCB directives ensures industries operate within the legal framework, avoiding legal disputes and ensuring uninterrupted operations.

- Technology advancements: Strict ETP norms compliance encourages industries to adopt advanced and efficient wastewater treatment methods leading to overall technological progress in the sector.

CPCB and NGT compliance for ETPs is important for legal adherence and environmental sustainability, public health and corporate reputation. Delhi Industries must prioritize this compliance to ensure their long-term viability, contributing positively to society.

FAQs

1. What is the importance of installing ETP plants?

Installing ETPs is important to treat industry wastewater, thus preventing environmental pollution and ensuring regulatory compliance.

2. What is CPCB and NGT ETP compliance?

Industries must ensure their ETPs adhere to the prescribed effluent discharge norms, implement advanced treatment processes and regularly monitor and report wastewater quality. The best quality ETPs designed by Green Genra adhere to the directives and norms of CPCB and NGT.

3. What are the challenges in achieving ETP compliance?

Achieving compliance for ETP involves addressing challenges like complex regulatory frameworks, technological limitations, financial constraints and the need for skilled personnel.

Ghaziabad has witnessed an increase in several industries in the past few years. The continuously rising population and a gro...

Effluent Treatment Plant (ETP) from reliable ETP Plant Manufacturers play a key role in reducing industrial pollution by trea...

With the increasing levels of water contamination in Ghaziabad because of growing industries and a growing population, wastew...

Green Genre is one of the best STP manufacturers in Noida that designs, produces and installs sewage treatment plants in vari...

Effluent Treatment Plants or ETPs are important for industries in Ghaziabad to ensure environmental compliance ensuring effec...

An effluent Treatment Plant or ETP is a crucial investment for industries seeking to manage wastewater according to environm...