Water Expo 2025 in New Delhi 28-30 August 2025 | Pragati Maidan, New Delhi India 20th Everything About Water Expo 2025 ...

How ETP Plants Help the Food Industry Meet Environmental Regulations

Food industry faces significant environmental challenges. It is important for food facilities to ensure sustainable operations and adhere to strict environmental norms. ETP Plant for food industry plays a significant role in helping food facilities manage their waste and meet the environmental norms.

What is ETP Plant?

An Effluent Treatment Plant or ETP is designed to treat waste water generated from industrial processes. These plants utilize many physical, chemical, and biological processes to remove contaminants from waste water ensuring that it is discharged as per the regulatory standards.

What are the key benefits of ETPs in the food industry?

- Adhere with environmental regulations: Environmental regulations pertaining to the discharge of waste water is strict and all industries including the food industry must comply with these norms to avoid huge fines and penalties. ETP plant for food industry ensures that the waste water is treated to the required standards, helping the companies adhere to local and international environmental laws.

- Reduction at environmental impact: Untreated waste water has devastating effects on the environment. ETPs reduce this impact by removing harmful pollutants ensuring the treated water is safe for reuse or discharge. This minimizes the carbon footprint of food industry on the environment.

- Recovery of valuable resource: ETP plant not only treats waste water but also enables the recovery of valuable resources. For instance biogas can be produced from organic waste and can be used as an energy source, minimizing the dependency on fossil fuels and promoting a circular economy within the food facility.

- Save costs: Implementing ETP in food industry can lead to significant cost savings in the long run. By treating and reusing water, food processing plants can minimize their consumption of fresh water. Also, energy generation from bio-gas lowers the operational costs.

- Increased public image: In eco-friendly market, consumers prefer brands that demonstrate a commitment to sustainability. By investing in ETP and promoting eco-friendly practices, food facilities can boost their public image and build trust with their consumers, fostering brand loyalty and market share.

Operation of ETP plant-

- Preliminary Treatment: The stage involves removal of large solids and debris through sedimentation and screening.

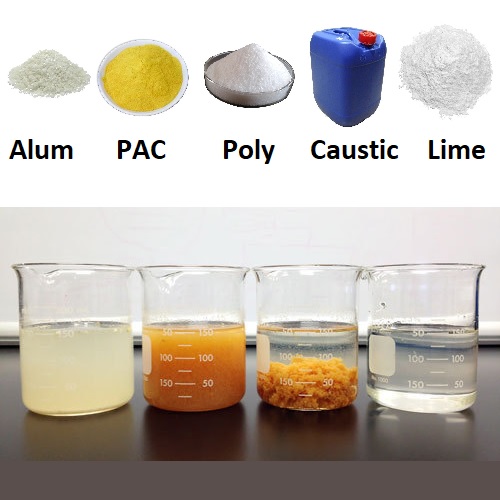

- Primary Treatment: Here the physical and chemical processes are used to remove suspended solids and organic matter.

- Secondary Treatment: In this stage, biological oxygen demand and chemical oxygen demand of waste water is reduced.

- Tertiary Treatment: The advanced treatment targets remaining impurities, including nutrients like phosphorous and nitrogen using various methods including filtration and ion exchange ensuring the highest quality of water.

- Disinfection: The treated water undergoes disinfection to remove pathogens and disinfected water is safe for reuse or discharge.

ETP is important for food industry helping the facility to reduce ecological impact and paving way for sustainable future.

FAQs

1. What is Effluent Treatment Plant?

ETP or the Effluent Treatment Plant is a facility designed to treat industrial waste water ensuring it meets environmental discharge standards.

2. Why is ETP important for Food Industry?

ETP is important in food industry as it ensures waste water is treated to meet the environmental regulations and minimize ecological impact.

3. How many treatment stages do ETP for food industry has?

ETP for food industry typically have five treatment stages- preliminary, primary, secondary, tertiary and disinfection.

Effluent Treatment Plant (ETP) from reliable ETP Plant Manufacturers play a key role in reducing industrial pollution by trea...

With the increasing levels of water contamination in Ghaziabad because of growing industries and a growing population, wastew...

Green Genre is one of the best STP manufacturers in Noida that designs, produces and installs sewage treatment plants in vari...

Effluent Treatment Plants or ETPs are important for industries in Ghaziabad to ensure environmental compliance ensuring effec...

An effluent Treatment Plant or ETP is a crucial investment for industries seeking to manage wastewater according to environm...

ETP or the Effluent Treatment Plant is designed to treat industrial wastewater by removing harmful chemicals, contaminants an...