Water Expo 2025 in New Delhi 28-30 August 2025 | Pragati Maidan, New Delhi India 20th Everything About Water Expo 2025 ...

How to design an oil grease separator for food processing plant?

Are you looking for the best quality grease separator for your food processing plant? If so, look no further and collaborate with an expert grease trap manufacturer who will design the apt great and oil separator as per the requirements of the food processing plant.

A grease trap or separator is designed thoughtfully to remove oil and grease from the waste waters and prevent the FOG- fats, oil and grease from entering the environment and sewage system. A grease separator performs this function effectively, provided they are designed and maintained properly.

Grease and oil; when they enter in the sewage system cause issues like blockage and accumulation. Over the time, these accumulated FOG deposits get larger as more grease and solid material builds up. Grease deposits minimize the capacity of sewer pipes causing sewage overflows, pungent smell and unhealthy environment.

The cleaning of grease deposits from sewers is a challenging work and can be harmful if not carried out immediately and this will come at considerable cost.

Why food processing Plant need to install grease trap?

All the food processing plants and factories are required to install the best quality grease and oil traps so that the FOG or the greasy materials will be separated from waste waters before passing to the communal sewage system.

Restaurants and food processing industries are required to install grease traps so that greasy materials will be separated from waste waters before passing to the sewage system. Food processing units and restaurants are the main source of the grease waste and so it is important that the grease traps used at these facilities are of best quality and properly designed so that they can effectively remove FOG, grease from waste water before it passes to the sewer system.

It is the responsibility of the food processing units to check

1. Whether the grease and oil separators are designed and constructed properly so that they effectively remove grease materials from the kitchen’s waste water before discharge to sewer system.

2. The grease trap is properly maintained so that it can continue to function as an effective grease removal equipment and so that kitchen hygiene is preserved.

3. Material removed from grease trap is handled and disposed of properly in order to maintain kitchen hygiene and protect the environment.

What kind of grease trap is best for food processing plant?

There are many kinds of grease traps available in the domain and they come in different sizes, models and with different price tags. It is imperative to choose the unit that will benefit the business the most.

Grease and oil separators improve the air quality in the area, and will eliminate foul smell. This means the employees will not have to worry about bad odor. With many benefits of grease traps for your food processing unit, it is important to collaborate with a renowned and experienced grease separator manufacturer to design the oil and grease separator for your food processing plant.

Effluent Treatment Plant (ETP) from reliable ETP Plant Manufacturers play a key role in reducing industrial pollution by trea...

With the increasing levels of water contamination in Ghaziabad because of growing industries and a growing population, wastew...

Green Genre is one of the best STP manufacturers in Noida that designs, produces and installs sewage treatment plants in vari...

Effluent Treatment Plants or ETPs are important for industries in Ghaziabad to ensure environmental compliance ensuring effec...

An effluent Treatment Plant or ETP is a crucial investment for industries seeking to manage wastewater according to environm...

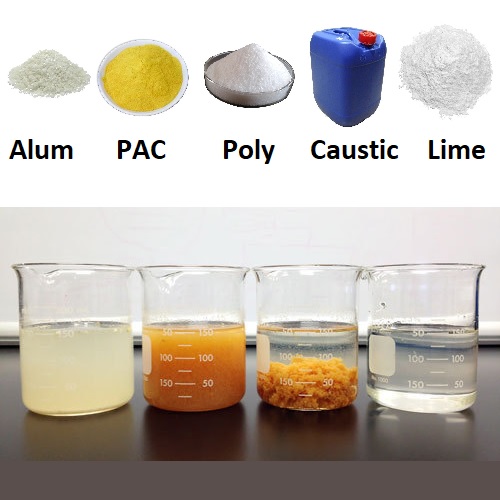

ETP or the Effluent Treatment Plant is designed to treat industrial wastewater by removing harmful chemicals, contaminants an...