Water Expo 2025 in New Delhi 28-30 August 2025 | Pragati Maidan, New Delhi India 20th Everything About Water Expo 2025 ...

The Efficient ETP Blueprint: A Step-by-Step Design Guide

Effluent treatment plant is important in the world of industrial waste management. The ETP not only ensure compliance with environmental norms but also contribute to conservation of the environment.

Here is a step-wide design guide or the ETP Blueprint that helps you design an efficient ETP that meets the specific needs.

- Assess Effluent characteristics: First step is the thoroughly assess the characteristics of the ETP. Analyze the physical, chemical and biological properties of wastewater. Consider key parameters that include pH, temperature, chemical oxygen demand, total suspended solids and presence of contaminants.

- Know the treatment objectives: Based on the characteristics of the effluent, know the treatment objective. The objectives should align with local regulatory norms and environmental guidelines. The common objectives include COD and BOD levels, neutralizing pH and removing toxic substances.

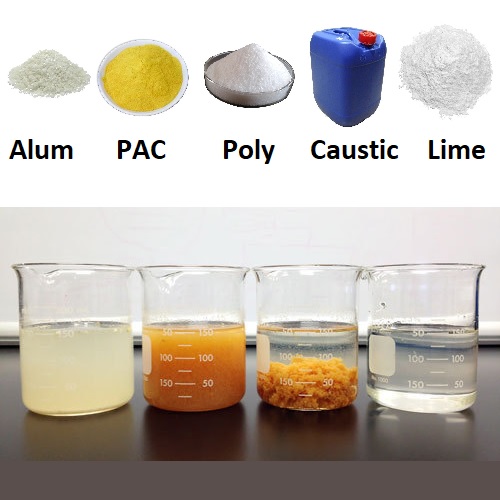

- Select the treatment technologies: It is important to choose the right treatment technology for efficiency of ETP. Based on the effluent characteristics and treatment objectives one may need a blend of physical, chemical and biological treatment methods. The common techniques include primary treatment, secondary treatment and tertiary treatment method.

- Design the treatment unit: Design the individual treatment units based on selected techniques. This involves determining size, capacity and configuration of each unit. The key considerations include flow rates, hydraulic retention time, and efficiency of each treatment stage. Also make sure that the units are designed for easy operation and maintenance.

- Integrate treatment system: Make sure that the flow of effluent from one unit to the next is seamless and overall system operates efficiently. This involves designing intermediate storage tanks, pumping systems and control mechanisms.

- Control systems: For controlling the ETP it is imperative to implement automation and control systems. This help monitoring and managing its performance. The cutting-edge control systems can optimize treatment processes, reduce operational costs and ensure compliance with regulatory norms.

- Testing: Before fully implementing ETP in your facility, conduct pilot testing to validate the design. Pilot tests help identify potential issues and allow for adjustments that help streamline the process.

- Management of sludge: Effective sludge management is an important part of ETP. Know the methods of sludge dewatering, treatment and disposal. This includes options like sludge drying beds, incineration and more.

- Maintenance: Create a detailed operation and maintenance plan to make sure long-term efficiency of the ETP. This includes regular inspections, preventive maintenance schedules and emergency response methods. The operating staff must undergo training on safety protocols and best practices.

- Continuous monitoring and improvement: It is important to implement continuous monitoring and improvement program. Regular review of performance data, audits and improvements are required. Also, facilities need to stay updated with the advancement in treatment technologies and regulatory changes to keep ETP efficient and compliant.

With the help of aforesaid ETP Blueprint efficient ETP can be designed that meets regulatory norms and contributes to sustainable environmental practices.

FAQs

1. What is benefit of ETP?

ETP ensures regulatory compliance and environmental protection by treating industrial wastewater.

2. Why is ETP Blueprint important?

ETP Blueprint is important as it provides a systematic and step-wise guide for designing efficient and effective wastewater treatment plant.

3. What is the main aim of ETP?

The main aim of ETP is to treat industrial effluent to meet the regulatory norms and reduce ecological impact.

Ghaziabad has witnessed an increase in several industries in the past few years. The continuously rising population and a gro...

Effluent Treatment Plant (ETP) from reliable ETP Plant Manufacturers play a key role in reducing industrial pollution by trea...

With the increasing levels of water contamination in Ghaziabad because of growing industries and a growing population, wastew...

Green Genre is one of the best STP manufacturers in Noida that designs, produces and installs sewage treatment plants in vari...

Effluent Treatment Plants or ETPs are important for industries in Ghaziabad to ensure environmental compliance ensuring effec...

An effluent Treatment Plant or ETP is a crucial investment for industries seeking to manage wastewater according to environm...