Water Expo 2025 in New Delhi 28-30 August 2025 | Pragati Maidan, New Delhi India 20th Everything About Water Expo 2025 ...

Responsibilities of ETP Manufacturers in Delhi NCR to Ensure CPCB Compliance

The primary goal of effluent treatment plants is to ensure industrial wastewater becomes safe before environmental release. These facilities help reduce pollution and protect water resources. But how can we verify these plants follow established standards? That is where the Central Pollution Control Board comes in. The CPCB has s guidelines to ensure ETPs operate while protecting Mother Nature.

The role of an ETP Plant Manufacturer in Delhi NCR becomes vital here. They help industries meet the CPCB rules by building plants that are efficient and eco-friendly.

Whether you’re looking for an ETP Plant Manufacturer in Noida, Gurgaon, or Ghaziabad, their efforts ensure clean water and a healthier planet. Let’s explore how these manufacturers work to meet the CPCB requirements and why their role is so important for our environment.

CPCB Compliance in Wastewater Management – Things to Keep in Mind

CPCB compliance protects Mother Nature and its habitats. Industries produce a lot of wastewater that may harm rivers, soil, or air if it’s not treated. This is where ETPs help. They clean the water by removing harmful chemicals and pollutants before releasing them.

The CPCB makes rules for wastewater treatment so industries follow a common standard. These regulations define permissible and prohibited discharge parameters. For instance, specific limits exist for oil, grease, and heavy metal concentrations in treated water.

For industries in Delhi NCR, following Central Pollution Control Board guidelines prevents penalties and supports community health. Companies can develop treatment plants that meet regulations by partnering with an experienced equipment manufacturer or ETP Plant Manufacturer in Gurgaon and surrounding areas.

These plants reduce expenses by treating & reusing water in the factories. It saves resources and, at the same time, reduces wastage.

When industries follow CPCB rules, they meet legal standards and show responsibility. The approach creates a safer environment while maintaining balance between industrial progress and ecological preservation.

Top CPCB Rules for Effluent Treatment Plants

There are specific rules for industries to manage wastewater. These guidelines define the standards that treated water must meet before it can be released.

One rule is about the pH level of treated water. The CPCB says treated water should have a pH level between 6.5 and 8.5. Another rule controls Biological Oxygen Demand (BOD), which shows how much organic pollution is in the water. Lower Biological Oxygen Demand indicates superior water quality.

Additional guidelines target hazardous substance removal, including heavy metals, oils, and chemical residues. Such pollutants may harm marine life alongside drinking water sources when treated improperly.

The guidelines also differ for various industries. Different industries have unique treatment standards. Textile manufacturing requirements differ significantly from pharmaceutical sector protocols. That’s why working with an experienced ETP Plant Manufacturer in Ghaziabad is important. They understand these industry-specific rules and build plants accordingly.

These guidelines also emphasise continuous monitoring and regular maintenance. Industries are required to keep records of water quality tests to show they are following the rules.

Industries help create cleaner rivers by following CPCB guidelines. These guidelines also make the drinking water safer. And it all starts with an efficient ETP built to meet these standards.

Role of ETP Manufacturers in Maintaining Compliance

ETP plant manufacturers in Delhi NCR help industries follow the guidelines as set by the Central Pollution Control Board or CPCB. Their efforts go beyond just building the plants. They also ensure these plants operate efficiently for years. Here are their dutiful responsibilities:

Efficiently Design the Plants

Manufacturers design plants that treat wastewater efficiently. In addition, they also study the type or volume of wastewater produced by a facility while developing a treatment system tailored to those specific needs. This way, they can control pollutants better while reducing harmful substances in the water.

Offering the Best Solutions

Different industries yield different wastewater. For instance, a textile factory releases dyes or chemicals. On the other hand, a food processing unit will generate organic waste. An experienced ETP plant manufacturer in Noida works with each industry to develop systems that address these unique challenges. Manufacturers ensure the wastewater is treated to meet CPCB requirements by customising solutions.

Ensuring the Right Methods for Installation

The efficiency of an ETP depends heavily on its installation. Improperly placing the equipment may result in inefficient operations or sudden breakdowns. Manufacturers take additional care to install the machinery or components correctly. They ensure the plant operates smoothly from day one. Proper installation helps them avoid problems while keeping the plant functioning as required by the guidelines.

Offering Maintenance Services

An ETP needs regular maintenance to stay compliant with the CPCB standards. Parts wear out over time, and system efficiency also declines. Manufacturers offer ongoing maintenance services like:

- Repairs

- Cleaning

- Replacement of components and more

With their services, the plant can operate with consistency while avoiding penalties or harm to Mother Earth.

Offering Innovative Training Programs

Even the best ETPs need skilled operators to run effectively. So, manufacturers train industry staff to operate the plant. They teach staff how to handle emergencies while maintaining optimal performance. The employees also learn about conducting regular quality checks on the treated water.

ETP plant manufacturers in Delhi NCR help industries treat wastewater responsibly by following the above steps.

Advanced Treatments Implemented by Green Genra

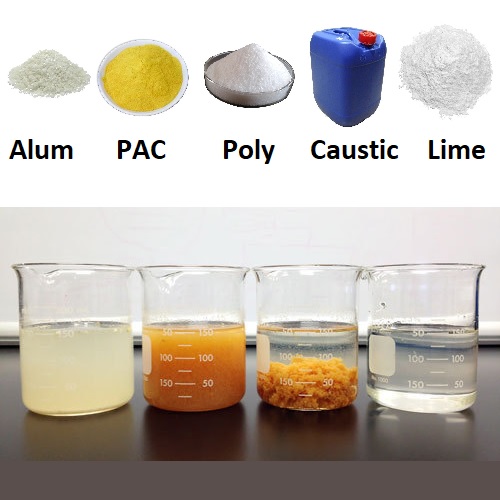

Treatment plant manufacturers or ETP manufacturers in Delhi NCR utilise cutting-edge technologies to process wastewater according to established environmental standards. The technologies help remove pollutants while making the water safe for reusing purposes. The following are the treatment methods that manufacturers implement currently –

Biological Treatment - An Environmental Friendly Choice

This eco-friendly process manages organic waste in wastewater. This cost-effective method introduces microorganisms (bacteria) into the system. The microorganisms feed on organic pollutants, breaking them into simpler harmful substances. This process reduces pollution alongside minimises the environmental impact of wastewater discharge. Biological treatment is for industries that generate an excessively high volume of biodegradable waste (food processing or agriculture-based units).

Ultraviolet Disinfection –

Natural Purification involves passing wastewater through specialised chambers. Ultraviolet light penetrates microorganism cell structures, disrupting harmful material. This technique eliminates bacteria and viruses without chemical intervention. The process serves as a final treatment stage, ensuring water safety for ecosystem release.

Membrane Filtration - An Advanced Method

Membrane Filtration represents an advanced purification technique. Such a method involves using specially designed membranes. These membranes trap unwanted particles while letting clean water pass through.

Any industry where accuracy in removing impurities is crucial – for instance – pharmaceuticals or chemicals – can consider this method. Membrane filtration also reduces the overall load on other treatment processes.

Reverse Osmosis – A Popular Method

Reverse Osmosis removes dissolved minerals and impurities by pushing water through specialised filtering membranes. The method forces liquid through microscopic screening surfaces.

These advanced technologies allow ETP Plant Manufacturers in Delhi NCR to provide effective as well as reliable wastewater treatment solutions.

Customisation of ETP Plants for Industry-Specific Needs

Different industries generate different types of wastewater. ETP Plant Manufacturers in Gurgaon and other areas create custom solutions to meet these needs.

The Textile Industry

Textile factories release dye-laden wastewater. Manufacturers build plants to remove colour and toxic chemicals.

The ETP Plants for Food Industry

Food industries produce waste with high organic content. ETPs for these industries focus on biological treatment methods.

The Pharmaceutical Domain

This industry generates wastewater with harmful chemicals. Plants are customised to remove hazardous compounds.

The Automotive Sphere

Automotive factories produce oil and grease in their waste. Specialised systems remove these impurities.

Automation & Monitoring Systems in ETPs

It is noteworthy to state that automation makes ETPs more efficient. Modern systems include software or remote monitoring to improve performance.

Using Smart Sensors

These sensors monitor water quality continuously, checking for pH, BOD or more.

Monitoring Remotely

Industries can monitor plant performance from anywhere using mobile apps or dashboards.

Alerts & Alarms

Automated systems send instant alerts to operators when something goes wrong.

Storing the Data

Automation systems store historical data for audits as well as regulatory checks.

Training and Support for Operational Excellence

For an ETP to work well, staffs needs proper training. ETP Plant Manufacturers in Noida offer understanding to teach operators about plant management.

Operators learn how to manage emergency scenarios while maintaining testing water quality. Training also covers how to keep up with record keeping (crucial for CPCB inspections).

Manufacturers also offer support while troubleshooting issues or replacing faulty parts. At the same time, they offer upgrades as regulations change. Such guidance ensures the plant remains compliant as well as efficient.

Collaboration with Environmental Regulators

Manufacturers work closely with regulators to make sure ETPs meet all legal requirements. They assist industries during inspections. They offer the documentation required for the CPCB approval.

This collaboration builds trust between industries. It also simplifies the compliance process while making it simpler for businesses to follow the rules.

Challenges Faced by ETP Manufacturers in CPCB Compliance

Building ETPs that meet CPCB rules is never easy. Here are some challenges & how manufacturers handle them.

Changing Regulations

Manufacturers adapt their designs to keep plants compliant as standards get stricter.

Cutting the Cost

Small businesses may struggle with costs. Manufacturers offer affordable solutions to meet their budgets.

Limited Space

Industries with limited space need compact ETPs. Manufacturers design systems that are save the space.

Training Everyone

Untrained staff can result in compliance issues. Manufacturers offer training programs to address the issue.

Future Trends – Ensuring Compliance & Regulations

Wastewater treatment is evolving with new trends. Such innovations help industries meet existing regulations while preparing for stricter environmental laws.

Effectively Integrating IoT

Modern sensor technologies transform treatment plant monitoring. Strategic sensor placement tracks critical water quality parameters – including pH levels, oxygen demand, and chemical composition.

These sensors send data to a central platform. The operators can access it on their computers or smartphones. This information lets industries identify or address issues immediately. So, it reduces downtime while ensuring compliance with the CPCB standards.

For example, an early alert system can notify operators if pollutant levels exceed acceptable limits. It prevents accidental environmental damage.

Introducing Green Solutions

Environmentally friendly tactics are gaining prominence in wastewater treatment. One such method is the use of constructed wetlands. Here, wastewater flows through the ponds or soil systems with specific vegetation.

These plants naturally break down pollutants to offer an alternative to mechanical treatment. Green solutions like these are especially beneficial for small industries that lack the resources for complex systems.

Systems that Come with AI Operations

Intelligent systems are introduced to improve ETP efficiency. Such systems use machine learning or data analytics to analyse plant operations while optimising processes like chemical dosing as well as energy consumption.

Reusing Water in an Effective Manner

Industries have started understanding the significance of reusing treated water in operations. Instead of discharging treated water, it is being repurposed for tasks like cooling machinery, cleaning, or even irrigation. Reusing water reduces the demand for fresh resources and lowers the environmental impact of industrial activities.

Some advanced ETPs are equipped with additional steps (such as reverse osmosis) to make treated water suitable for quality applications. Water reuse not only helps industries comply with emerging regulations but also supports sustainable resource management.

Partnering with the Right Manufacturer for Compliance

Hiring the right ETP Plant Manufacturer in Delhi NCR helps meet the CPCB guidelines. The manufacturers design plants that not only treat wastewater but also help protect the environment.

Look for a partner who understands your industry – whether you need an ETP Plant Manufacturer in Ghaziabad, Gurgaon, or Noida. A manufacturer will offer efficient systems, proper training, as well as long-term support

Ghaziabad has witnessed an increase in several industries in the past few years. The continuously rising population and a gro...

Effluent Treatment Plant (ETP) from reliable ETP Plant Manufacturers play a key role in reducing industrial pollution by trea...

With the increasing levels of water contamination in Ghaziabad because of growing industries and a growing population, wastew...

Green Genre is one of the best STP manufacturers in Noida that designs, produces and installs sewage treatment plants in vari...

Effluent Treatment Plants or ETPs are important for industries in Ghaziabad to ensure environmental compliance ensuring effec...

An effluent Treatment Plant or ETP is a crucial investment for industries seeking to manage wastewater according to environm...