Water Expo 2025 in New Delhi 28-30 August 2025 | Pragati Maidan, New Delhi India 20th Everything About Water Expo 2025 ...

Top Challenges and Solutions for Designing an ETP Plant for Food Processing Units

Food processing plants face significant challenges in managing industrial wastewater. These facilities use large volumes of water and various chemicals during production to create complex waste streams that can harm the environment if not properly treated. The wastewater typically contains organic matter, grease, and industrial chemicals that make it unsuitable for direct reuse or environmental release.

The ETP plant for food industry provide a critical solution for food production facilities. These specialised systems are carefully designed to clean contaminated water, helping businesses meet environmental regulations while maintaining operational efficiency. By implementing robust treatment infrastructure, companies can reduce their pollution impact and find innovative ways to reuse water in non-consumptive applications.

Introducing ETP Plants in the Food Industry – Their Role

Wastewater management represents a fundamental challenge for food processing facilities. Each day, these operations generate complex liquid waste streams containing organic matter, oils, and industrial cleaning agents. Without comprehensive treatment, these waste streams pose severe environmental threats, potentially contaminating water resources and degrading soil quality.

Protecting Environmental Health

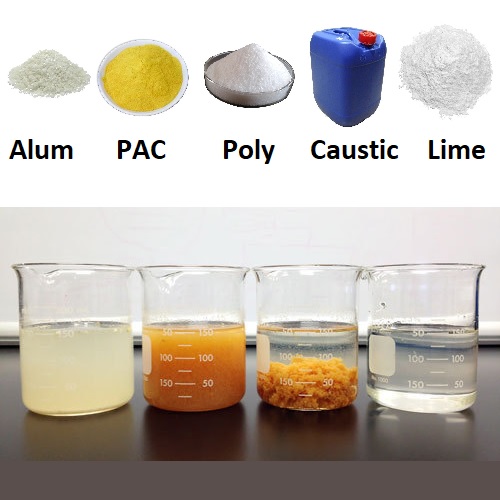

Specialised water treatment systems offer a robust solution for food production environments. These infrastructure designs meticulously filter and purify contaminated water streams, systematically removing:

• Suspended solid particles

• Harmful chemical residues

• Organic waste compounds

• Potential environmental pollutants

Economic and Operational Benefits

Treatment plants deliver far-reaching advantages that extend well beyond regulatory requirements:

• Significant water conservation through strategic recycling

• Reduced operational expenses by minimising freshwater consumption

• Creation of reusable water for secondary applications like facility cleaning and landscape irrigation

• Enhanced workplace environmental standards

Scalable Solutions for Diverse Food Production

From compact dairy operations to expansive food manufacturing complexes, effluent treatment systems offer adaptable technologies. These solutions demonstrate a committed approach to:

• Environmental stewardship

• Sustainable industrial practices

• Responsible resource management

Building Industry Reputation Through Responsible Practices

Food processing organisations communicate a powerful message by implementing comprehensive water treatment strategies. They showcase commitment to:

• Ecological preservation

• Responsible industrial operations

• Long-term environmental sustainability

Modern effluent treatment plant represent more than technological infrastructure. They embody a progressive approach to industrial water management, bridging operational efficiency with environmental protection.

Effluent Traits in Food Processing – Understanding the Ins & Outs

Here are the effluent qualities in food processing –

Nature of Food Processing Waste water

Food processing facilities generate complex wastewater with unique characteristics that challenge traditional treatment approaches. Understanding these effluent traits is crucial for designing effective ETP plant for food industry that protect water resources and minimise ecological impact.

Organic Matter Dynamics

Food processing operations involving fruits, vegetables, and grains create wastewater rich in organic materials. These organic compounds decompose rapidly, potentially causing severe environmental disruptions. When released untreated, these materials consume oxygen in aquatic ecosystems, threatening marine life and disrupting delicate ecological balances.

Lipid and Grease Contamination

Cooking processes introduce substantial quantities of oils and fats into wastewater streams. These lipid contaminants create significant treatment challenges, forming sticky, resistant layers that complicate purification processes. Their presence increases water viscosity and requires specialised separation techniques to remove and process effectively.

Chemical Cleaning Agent Complexities

Industrial food processing facilities rely on extensive cleaning protocols involving detergents, sanitizers, and chemical agents. These substances introduce complex chemical compositions into wastewater, potentially containing phosphates, chlorine compounds, and synthetic surfactants. Such chemical interactions can create environmental hazards and necessitate sophisticated neutralisation strategies.

Fluctuating Hydraulic Characteristics

Wastewater generation in food processing environments follows an irregular pattern. Production cycles, cleaning schedules, and operational variations create non-uniform flow rates, presenting significant challenges for consistent treatment methodologies. Treatment systems must demonstrate remarkable adaptability to manage these dynamic hydraulic conditions effectively.

Nutrient Concentration Concerns

Nitrogen and phosphorus represent critical nutrient parameters in food processing effluents. While essential for biological systems, their uncontrolled discharge can trigger eutrophication—a process causing excessive algal growth in water bodies. This phenomenon disrupts aquatic ecosystems, reduces oxygen levels, and can lead to widespread environmental degradation.

Strategic Treatment Considerations

Comprehensive effluent management requires a holistic approach that addresses multiple contamination vectors. By developing nuanced treatment strategies that account for these complex characteristics, environmental treatment plants can achieve multiple objectives: protecting water resources, supporting ecological sustainability, and enabling water reuse technologies.

Effective wastewater management transcends mere regulatory compliance. Understanding the intricate traits of food processing effluents provides the foundational knowledge necessary to design sophisticated, adaptable treatment solutions.

Key Design Considerations for Food Industry ETPs

Several factors need attention when designing an ETP plant for food industry. These include the following –

Strategic Foundational Planning for Environmental Treatment Facilities

Designing an environmental treatment facility in the food processing sector requires careful consideration of multiple interconnected elements. Success depends on understanding how each design component contributes to operational excellence, safety, and environmental compliance.

Flooring System Considerations

Facility flooring is a critical infrastructure component that directly impacts operational hygiene and long-term performance. The ideal flooring system must be durable, seamless, and resistant to harsh chemical treatments. Smooth, impenetrable surfaces prevent bacterial growth in microscopic cracks, creating a strong defence against potential contamination.

Strategic Facility Location

Selecting the accurate facility location needs comprehensive strategic evaluation. Placing the treatment centre close to primary wastewater generation sources reduce transportation costs and infrastructure needs. Accessibility remains crucial, ensuring smooth maintenance and emergency response capabilities.

Design of the Drainage System

The drainage infrastructure serves as the facility's circulatory system. Engineered drainage solutions must go beyond basic liquid redirection, providing comprehensive contamination prevention and streamline sanitation capabilities.

Operational Layout Optimisation

Facility layout design directly impacts operational efficiency, worker safety, and treatment process effectiveness. Strategic equipment positioning and thoughtful spatial planning create an environment that maximises productivity while minimising contamination risks.

Equipment Selection Strategy

Equipment procurement is a significant investment with long-term operational consequences. Selecting treatment technologies requires careful evaluation of facility-specific needs, anticipated waste composition, and performance requirements.

Holistic Performance Integration

Successful facility design goes beyond individual component excellence. Operational mastery emerges through sophisticated integration, where flooring, location, drainage, layout, and equipment function as a unified, responsive system.

Food processing organisations can transform waste management from a regulatory requirement into a strategic competitive advantage. This requires a multidimensional approach to facility design that considers every aspect of environmental treatment infrastructure.

Challenges Confronting Food Processing Facilities in Wastewater Treatment Plant Design

Developing an effective waste water treatment system presents multifaceted obstacles for food processing establishments. Successful implementation requires strategic navigation of complex technical and operational challenges.

Dynamic Landscape of Wastewater Management

Food processing facilities face complex challenges in developing environmental treatment solutions. These challenges require sophisticated strategies and technical expertise.

Composition Variability: A Persistent Complexity

Raw material diversity creates uncertainties in wastewater characteristics. Each production cycle introduces unique chemical compositions, making standardised treatment methodologies insufficient. Different processing facilities generate varying wastewater profiles based on their specific production requirements.

Spatial Configuration Limitations

Physical infrastructure constraints challenge treatment system design. Manufacturing facilities often operate in restricted spaces, requiring compact, efficient solutions. Engineers must optimise every square meter through innovative design strategies.

Financial Investment Barriers

Economic limitations significantly impact treatment facility development, especially for small and medium-scale manufacturers. Substantial upfront investments create considerable entry barriers for advanced treatment technologies.

Regulatory Compliance Complexities

Environmental protection regulations represent a dynamic landscape. Regional legislative frameworks vary dramatically, demanding nuanced understanding and precise implementation of treatment protocols.

Operational Sustainability Challenges

Sustained performance depends on expert maintenance personnel and operational awareness. Many manufacturing units struggle with the technical expertise required for sophisticated treatment systems.

Integrated Strategic Approach

Navigating these challenges demands a holistic perspective. Collaborative engagement between environmental engineers, manufacturing experts, and technology innovators becomes essential.

Transformative Potential

These challenges represent opportunities for technological innovation and operational refinement. Organisations embracing comprehensive, adaptable strategies can transform obstacles into competitive advantages.

By developing sophisticated environmental treatment solutions, food processing units can address ecological responsibilities, regulatory requirements, and operational efficiency simultaneously.

Challenges with Effluent Treatment Plant Design

Establishing an efficient ETP plant for food industryrequires strategic solutions to overcome operational hurdles. Here's a comprehensive methodology to addressing critical design challenges:

System Adaptability

Developing modular ETP configurations enables dynamic response to evolving wastewater characteristics. Modular designs provide critical flexibility, allowing seamless transitions between different effluent compositions without requiring extensive system reconstruction.

Spatial Optimisation

Implementing innovative architectural strategies maximises limited industrial spaces. Vertical engineering techniques and multi-purpose equipment enable compact plant installations, making ETPs feasible for facilities with restricted physical footprints.

Economic Manufacturing

Leveraging local resources and streamlined technological approaches significantly reduces implementation expenses. Strategic material selection and simplified technological frameworks help organisations balance financial constraints while maintaining robust treatment capabilities.

Regulatory Compliance

Collaborating with specialised environmental and legal professionals ensures continuous alignment with regional environmental standards. Proactive monitoring and systematic plant updates guarantee sustained regulatory adherence, minimising potential legal complications.

Operational Expertise

Comprehensive workforce training programs are essential for maintaining smooth ETP plant for food industryfunctionality. Structured educational initiatives combined with progressive automation technologies reduce manual intervention, enhancing overall system reliability and operational efficiency.

By systematically addressing these fundamental challenges, food processing facilities can develop robust effluent treatment infrastructure that simultaneously protects environmental ecosystems and supports sustainable business operations.

Technological Innovations in ETP Design for the Food Industry

The following are the technological innovations in the ETP design for the recent-world food industry–

Revolutionary Filtration Technologies

Modern environmental treatment systems represent a quantum leap in water purification capabilities. Advanced filtration mechanisms now enable unprecedented levels of particulate removal, fundamentally transforming waste management strategies.

Biological Restoration Methodologies

Natural microbial ecosystems offer profound organic matter decomposition capabilities. Strategic deployment of specialised microorganism colonies enables efficient, environmentally harmonious waste transformation processes.

Continuous Performance Monitoring

Sophisticated sensor networks now provide instantaneous performance insights, revolutionising operational transparency and responsiveness. Comprehensive monitoring systems enable rapid diagnostic interventions and proactive maintenance strategies.

Energy Optimisation Strategies

Contemporary treatment systems prioritise energy efficiency, integrating renewable technologies and intelligent power management frameworks. These innovations significantly reduce operational expenses while minimising environmental footprints.

Spatial Optimisation Technologies

Engineering advancements have produced compact, high-performance treatment systems capable of delivering exceptional results within constrained physical environments. These innovations address critical spatial limitations facing modern manufacturing facilities.

Integrated Transformation Framework

These technological innovations collectively represent a paradigm shift in environmental treatment system design. Food processing facilities can now access unprecedented levels of operational efficiency, environmental responsibility, and economic optimisation.

Future-Oriented Perspective

Technological evolution in environmental treatment systems continues accelerating, promising increasingly sophisticated solutions. Food processing organisations embracing these innovations position themselves at the forefront of sustainable industrial practices.

By integrating cutting-edge technologies, manufacturers can simultaneously address environmental responsibilities, operational challenges, and economic constraints. These advancements transcend traditional waste management approaches, representing a holistic transformation of industrial environmental stewardship.

Case Studies: Successful ETP Implementations in the Food Industry

Here are some real-world case studies to denote successful ETP implementations in the food industry –

Dairy Plant

A dairy plant in a small town faced wastewater issues. With an ETP, they reduced pollution by 80%. The treated water was reused for cleaning, saving costs.

Fruit Processing Unit

A fruit processing factory installed an ETP to manage high organic waste. The system’s biological treatment reduced environmental damage and made operations sustainable.

Meat Processing Factory

A meat unit added advanced filters to its ETP plant for food industry. This ensured compliance with strict regulations while protecting nearby rivers.

Comprehensive Maintenance and Performance Enhancement Strategies for Environmental Treatment Facilities

The following are the maintenance tips to improve performance strategies in the food processing units:

Systematic Cleaning and Operational Integrity

Maintaining environmental treatment systems demands rigorous, methodical approaches to preserve operational excellence. Comprehensive cleaning protocols represent the foundational cornerstone of sustained performance and long-term reliability.

Water Quality Verification Frameworks

Continuous quality assessment ensures treatment effectiveness and regulatory compliance. Systematic testing protocols provide critical insights into system performance and potential improvement opportunities.

Strategic Equipment Modernisation

Technological evolution demands periodic equipment upgrades to maintain operational efficiency. Systematic replacement of outdated infrastructure enables enhanced performance and reduced long-term operational expenses.

Workforce Capability Enhancement

Skilled personnel represent the most critical asset in maintaining complex treatment systems. Comprehensive training programs develop workforce capabilities and prevent potential operational disruptions.

Professional Servicing and Maintenance Protocols

Systematic professional interventions address potential wear and performance degradation. Structured maintenance schedules ensure consistent operational reliability and extended system longevity.

Holistic Performance Management

Successful environmental treatment facility management requires integrated, multidimensional approaches. Organisations must develop comprehensive strategies addressing technological, human, and operational dimensions. Performance management principles encompass continuous improvement frameworks, systematic performance tracking, and more.

Effluent Treatment Plants clean wastewater, protect the environment, and save resources. By designing the right ETP plant for food industry, we can reduce pollution and reuse water effectively.

Together, we can build cleaner factories and a greener prospect for everyone. Let’s work toward sustainable food processing that cares for the planet.

An effluent Treatment Plant or ETP is a crucial investment for industries seeking to manage wastewater according to environm...

ETP or the Effluent Treatment Plant is designed to treat industrial wastewater by removing harmful chemicals, contaminants an...

Food processing plants face significant challenges in managing industrial wastewater. These facilities use large volumes of w...

The primary goal of effluent treatment plants is to ensure industrial wastewater becomes safe before environmental release. T...

To ensure a sustainable environment, Central and State Pollution control boards have made certain mandatory aspects that ever...

Indian Businesses need to comply with numerous environmental norms to ensure sustainable development and minimize pollution. ...