Water Expo 2025 in New Delhi 28-30 August 2025 | Pragati Maidan, New Delhi India 20th Everything About Water Expo 2025 ...

Understanding Different Types of ETP Plants for the Food Industry?

To ensure a sustainable environment, Central and State Pollution control boards have made certain mandatory aspects that every industry must incorporate and follow. One such aspect is installing an Effluent Treatment Plant in every industry that generates harmful effluents.

An effluent Treatment Plant or ETP is a facility that is designed to treat industrial wastewater by removing harmful contaminants, pollutants and toxic materials before releasing it into the environment. The food industry requires ETP to manage wastewater containing oils, organic matter, grease and chemicals.

The Effluent Treatment solutions for food industry ensure compliance with the environmental norms by treating and recycling wastewater, reducing pollution and safeguarding ecosystems. They promote sustainable operations while preventing contamination of water resources and maintaining public health.

ETP plant types for the food industry

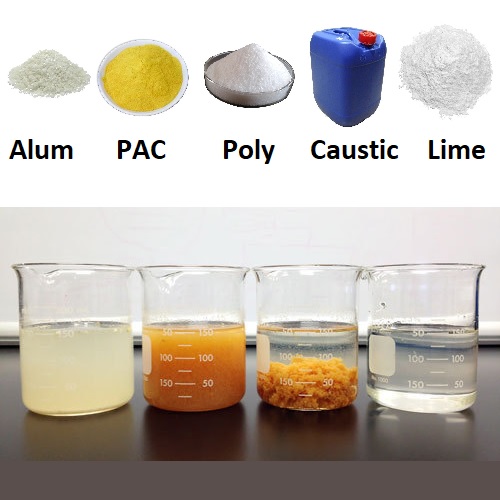

- Conventional ETP: It is a commonly used Effluent Treatment Plan equipment for food industry generating oily or greasy water. The ETP uses chemical processes like flocculation, coagulation and precipitation to remove the suspended solids, organic matter and oils. The process adds coagulants to remove suspended solids and oils. The benefits include quick treatment for effluents with high concentrations of non-biodegradable pollutants. The ETP plan is used in edible oil refining plants, soft drink bottling units and food packaging industries.

- Membrane Bioreactor System (MBR): The ETP uses advanced filtration methods like reverse osmosis, ultra-filtration and nanofiltration methods. It removes dissolved solids, pathogens, and fine particles. This ETP plant generates the best quality water for reuse. It also effectively removes even minute impurities. The common applications of MBR ETP are beverage production, bottled water plants, and industries requiring the best quality recycled water.

- Sequencing batch reactors (SBR): This ETP design for food processing treats wastewater in batches through aeration and settling cycles. The process in this ETP operates in batches, alternating between aeration and settling phases for treating wastewater biologically. The benefits of SBR ETP are that it handles variable loads effectively and produces the best quality treated effluent. The common applications are medium to large-scale food processing plants with fluctuating wastewater volumes.

- Activated Sludge Process (ASP): It is a biological treatment method that is commonly used in the food industry to treat wastewater. In ASP, the wastewater is aerated in a tank to promote the growth of microorganisms that consume organic matter and convert it into biomass. The mixture of wastewater and microbial biomass is then settled in a clarifier, separating the treated water from the sludge. A portion of sludge is recycled back into the aeration tank to maintain microbial activity and the excess is disposed of safely. ATP is ideal for treating effluents from dairy, meat, and beverage industries, ensuring environmental compliance.

- Anaerobic Digestion Systems: This ETP treats high-strength organic waste in the absence of oxygen, converting it into biogas and digestate. The biogas created can be used as an alternative fuel, thus reducing energy costs. The anaerobic digestion system handles the high organic loads efficiently. They are used in beverage manufacturing and industries producing high-strength organic effluents.

- Constructed Wetlands: Constructed Wetlands are the natural and eco-friendly ETP technology in food manufacturing facilities. They are used to treat wastewater. The system resonates the natural wetlands, using plants, soil and microorganisms to remove contaminants. Wastewater flows through vegetation and substrate layers, where the pollutants are broken down biologically or filtered out. The constructed wetlands are effective for treating organic-rich wastewater from small-scale food industries such as vegetable or fruit processing. They are cost-effective and require less energy, enhancing sustainability and offering ecological benefits.

How to choose the right ETP plant for the food industry?

Choosing the right Effluent Treatment Plant for the food industry involves understanding the specific wastewater features, operational goals and regulatory norms. Here are the important factors to guide the decision.

- Analyze wastewater characteristics: Before choosing wastewater treatment plants for food processing facilities, conduct a thorough analysis of wastewater generated. Assess the key factors including organic load, suspended solids, pH levels and toxic contaminants present in the water. A detailed analysis ensures the ETP design is according to the specific pollutants and treatment needs.

- Industry-Specific: Different segments of the food industry produce varying types of effluents. For instance, the dairy industry produces high organic content and fats, meat processing facility produces effluent rich in proteins, grease and oils and the beverage industry generates effluent with dissolved solids. It is advisable to choose the ETP system according to the unique challenges faced by the specific industry.

- Treatment Goals: It is important to define the primary treatment objective. These include meeting local norms for effluent discharge, focusing on recycling water for internal processes like cleaning or cooling, reducing operational and maintenance costs and adopting eco-friendly and energy-efficient systems.

- Assess the ETP types: The next step is to match the ETP type to the wastewater profile. Consider various types of Effluent treatment plants available for food industries and install the one that best suits the wastewater profile.

- Plant Capacity: Choose the ETP plant for your food industry according to your facility’s wastewater generation capacity. Take into account fluctuations in production and seasonal variations to avoid overloading the plant.

- Evaluate cost and maintenance: Analyze the capital investment, operating expenses, and maintenance needs. Choose an ETP with energy-efficient components and minimal downtime to reduce costs over time.

- Check the Space Availability: Assess the available space in your food facility for installing food industry wastewater treatment technologies. If your food facility has little space then the Sequencing Batch Reactors system is ideal.

- Environmental Regulations Compliance: Make sure the chosen ETP complies with national and local environmental norms for wastewater discharge.

- Sustainability: It is advisable to choose an ETP plant that recycles water and produces biogas. Sustainable ETPs like constructed wetlands enhance corporate responsibility and minimize ecological impact.

- Vendor Expertise and Support: It is imperative to choose a professional ETP plan manufacturer who has experience and expertise in designing and maintaining ETPs for the food industry. Make sure the ETP vendors also provide post-installation support, training and regular maintenance.

Choosing the right ETP for the food industry requires a careful balance of environmental, technical and economic considerations. The right effluent treatment plant not only protects the environment but also boosts operational efficiency and long-term profitability.

What are the future trends in ETP in the food industry?

As the food industry evolves, food processing ETP requirements are becoming increasingly innovative to address rising environmental challenges. Here are some of the future trends in ETPs in the food industry-

- Cutting-edge biological treatment method: This method uses enhanced microbial technologies for faster and more efficient treatment of organic waste in the food industry. The method uses specialized bacteria strains and enzymes tailored to food industry effluents. The biological treatment method uses the bio-augmentation process to boost microbial activity and hybrid systems combine aerobic and anaerobic processes. Other innovations like Membrane bioreactors and sequencing batch reactors are being optimized for energy efficiency and higher throughput. Also, anaerobic digestion is gaining importance for its capacity to treat high-strength organic waste while generating renewable biogas, converting waste into resources. These future trends ensure cost-effective, sustainable and regulatory compliance with strict environmental norms.

- Adoption of Membrane-based technologies: The adoption of membrane-based technologies is revolutionary in sustainable wastewater management in food industry. The trend offers advanced filtration systems like reverse osmosis, ultra-filtration and nano-filtration method to achieve superior wastewater treatment. The system removes dissolved solids, pathogens and trace contaminants enabling the reuse of treated water for cleaning, cooling or other industrial processes. Innovations in membrane durability, cleaning methods and fouling resistance are minimizing operational costs, and boosting efficiency. These ETP system supports water conservation, and compliance with strict environmental norms, making them a pillar for sustainable wastewater management in food industries.

- Zero Liquid Discharge: Zero Liquid Discharge is an emerging trend in ETPs for the food industry. It emphasizes complete water recovery and eliminating wastewater discharge. These systems integrated cutting-edge technologies like reverse osmosis, evaporation and crystallization to treat effluents and recover water for reuse in processes like cleaning and cooling. The zero liquid discharge ETP is important in water-scarce regions and industries facing strict environmental norms. By adopting this system, the food industry not only achieves regulatory compliance but also supports eco-friendly goals, minimizing the water footprint while ensuring resource conservation.

- Internet of Things Integration: IoT-enabled ETP is a significant future trend for the food industry, enabling real-time monitoring and automation of wastewater treatment processes. The IoT sensors track important parameters providing instant data for better decision making and operational control. The cloud-based platforms allow centralized monitoring across multiple facilities and the predictive maintenance reduces downtime and operational costs. The automation system adjusts treatment processes ensuring compliance with the environmental norms even with fluctuating wastewater loads. IoT - IoT-driven effluent treatment plant for the food industry boosts efficiency, sustainability and reliability in wastewater management.

- Energy Efficient Systems: Energy Efficient ETPs are an important future trend for the food industry focusing on minimizing the carbon footprint and operational costs of wastewater treatment. The cutting-edge technologies optimize resource usage during aeration and sludge management. Anaerobic digesters treat high-strength organic waste and generate biogas as a renewable energy source. The solar-powered ETPs and smart energy monitoring systems boost sustainability.

- Artificial Intelligence and Machine Learning: One of the best practices for ETP in food industry is the integration of AI and ML. The AI-driven systems analyze real-time data to predict the treatment performance, optimize chemical dosing and adjust aeration rates dynamically. These technologies support predictive maintenance, identifying potential equipment failures even before they occur, and reducing downtime and costs. AI and ML automate complicated decision-making processes, ensuring consistent compliance with environmental norms and adapting to various wastewater loads.

- Sustainable and Green ETPs: Sustainable and green ETPs are a growing trend in the food industry, emphasizing eco-friendly methods to reduce the ecological impact. These ETPs leverage natural processes like constructed wetlands to treat wastewater using plants and microorganisms. By integrating water recycling and nutrient recovery, sustainable ETPs align circular economy norms, helping the food industry meet its environmental goals while promoting resource conservation and biodiversity.

- Hybrid ETPs: Hybrid ETPs are the emerging future trend in the food industry, blending multiple treatment technologies to address diverse issues and complex wastewater features. These systems integrate chemical, biological and physical processes, offering all-round solutions for treating both organic and inorganic pollutants. For instance, the hybrid ETP may use cutting-edge oxidation processes for hard-to-degrade contaminants, followed by biological treatments like activated sludge or anaerobic digestion to manage organic loads. The flexible and modular approach boosts efficiency, and adaptability making hybrid ETPs perfect for dynamic food processing operations.

- Circular Economy Integration: The Circular Economy Trend in ETPs is a revolutionary future trend for the food industry, focusing on converting wastewater into valuable resources. These systems emphasize the recovery of nutrients like nitrogen and phosphorous for fertilizers, conversion of organic sludge into biogas or compost and recycling of treated water for cleaning or irrigation. The state-of-the-art technologies enable the extraction of byproducts like oils and proteins from effluents, further reducing waste. By synchronizing with the circular economy norms, ETPs reduce ecological impact while also creating economic opportunities, fostering a sustainable future and resource efficiency in the food industry’s wastewater management system.

The future trends of ETPs in the food industry are driven by innovation, sustainability and efficiency. The cutting-edge technologies will redefine how wastewater is managed. By adopting these trends, food industries can meet the regulatory demands, minimize ecological impact achieve long-term cost savings and promote sustainability.

FAQs

1. Why Effluent Treatment Plant is important to the food industry?

Effluent Treatment Plant is important for the food industry to manage wastewater, ensuring ecological compliance, sustainability and safe effluent disposal.

2. What are various types of ETPs for the food industry?

The food industry uses various types of ETPs, including chemical treatment, biological treatment, zero liquid discharge and hybrid ETPs customized to specific wastewater characteristics of the food industry.

3. How to choose the right ETP for the food industry?

Choosing the right ETP for the food industry involves analyzing wastewater characteristics, treatment goals, regulatory norms and cost-effectiveness.

4. What is the approximate cost of ETP for the food industry?

ETP plant cost for food processing varies based on the capacity and technology.

Are you planning to install ETP (Effluent Treatment Plant) or STP (Sewage Treatment Plant) in India? If so, understand the di...

Ghaziabad has witnessed an increase in several industries in the past few years. The continuously rising population and a gro...

Effluent Treatment Plant (ETP) from reliable ETP Plant Manufacturers play a key role in reducing industrial pollution by trea...

With the increasing levels of water contamination in Ghaziabad because of growing industries and a growing population, wastew...

Green Genre is one of the best STP manufacturers in Noida that designs, produces and installs sewage treatment plants in vari...

Effluent Treatment Plants or ETPs are important for industries in Ghaziabad to ensure environmental compliance ensuring effec...